███

███ ░░░ ███

█████████████ █████ ████ ███████ ████ █████ █████ ████████ ██████ ███████

░░███░░███░░███ ░░███ ░███ ░░░███░ ░░███ ░░███ ░░███ ░░███░░███ ███░░███░░░███░

░███ ░███ ░███ ░███ ░███ ░███ ░███ ░░░█████░ ░███ ░███ ░███████ ░███

░███ ░███ ░███ ░███ ░███ ░███ ███ ░███ ███░░░███ ░███ ░███ ░███░░░ ░███ ███

█████░███ █████ ░░████████ ░░█████ █████ █████ █████ ██ ████ █████░░██████ ░░█████

░░░░░ ░░░ ░░░░░ ░░░░░░░░ ░░░░░ ░░░░░ ░░░░░ ░░░░░ ░░ ░░░░ ░░░░░ ░░░░░░ ░░░░░

Things you might consider if this is your first time buying a suppressor.

Consider reading this FAQ

How does all this stuff go together?

Generally there are threads on the muzzle end of your firearm's barrel. But how does one mount a suppressor? There are two options:

- Quick Detach - A muzzle brake threads on to your barrel. There is a corresponding mount that threads into the rear of your suppressor. The muzzle device threads, locks, or somehow attaches into the mount to attach the suppressor to the end of your barrel.

- Direct Thread - Threads directly on to the muzzle of your barrel and into the back of the suppressor. No quick detach capabilities, much lighter and shorter than a QD system. This option is better if you will never plan to remove the suppressor once its installed.

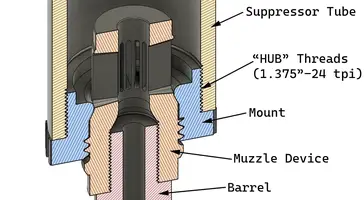

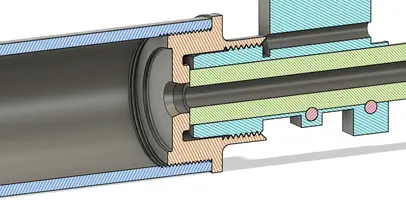

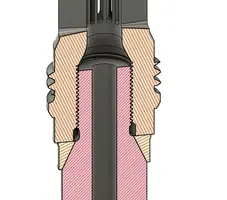

Below is a cutaway example of a QD muzzle device and HUB mount system.

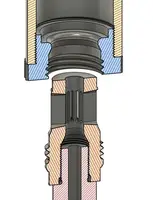

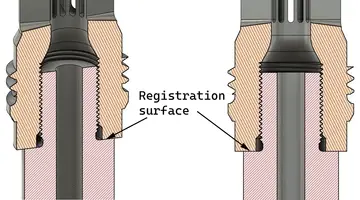

Below is a cutaway example of the same QD system with the suppressor detached.

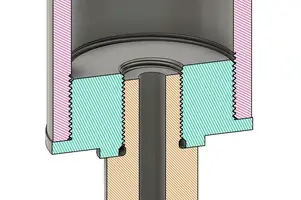

Below is a cutaway example of a suppressor attached with a direct thread HUB mount.

What is HUB threading and why is it important?

HUB threads, AKA SilencerCo "Bravo" threads, AKA 1.375-24 threads are all the rage these days but for good reason. Basically, HUB is an unofficial standard in the suppresssor industry where the rear of the suppressor tube has female threads of the 1.375"-24tpi size. That allows you to pick and choose whatever brand of mount and muzzle device you want as long as the mount has male 1.375-24 threads on it for the suppressor to thread on to. In years past each suppressor manufacuter had their own proprietary muzzle devices so when you bought a suppressor the tube had an integrated mount. That meant that you were locked in to the ecosystem of that brand's muzzle devices. Now that a lot of manufacturers are selling HUB threaded suppressors you can freely install the flavor of mount that works with your muzzle devices and own many different brands of suppressor without too many headaches.

Types of muzzle device seating methods.

There are a few different types of muzzle device "seating", "registration", or "indexing" methods. In order to understand how these muzzle devices work you need to be familiar with the concept of clearances. It is a fact that there is clearance between male and female threads. Clearance is basically a gap between the outer size of the male threads and the inner size of the female threads. The clearance between the two is necessary so that they thread together smoothly. A good example of these clearances can be seen if you thread a muzzle device on to a barrel without tightening it, then try to wiggle the muzzle device back and forth. You'll notice that even though the two are threaded together there is still enough of a gap betwen the two parts that the muzzle device is able to wiggle around. The threads, while they should be concentric with the bore, aren't what hold the muzzle device concentric. The way concentricity is achieved is by tightening the muzzle device against a reference surface that is machined with a very close tolerance in relation to the bore of the barrel. There are a few different locations for these reference surfaces on different styles of mounting systems.

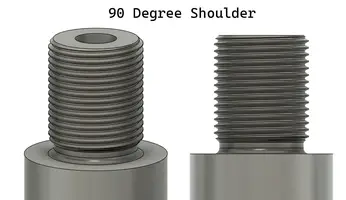

- Shoulder Indexing - Most common style, seats on a 90 degree shoulder. Found on most types of domestically produced barrels and firearms. The surface of the barrel that the muzzle device is tightened against is at a 90 degree angle to the bore.

- Face Indexing - Commonly used on european handguns, also soviet bloc weapons because they may not have threads concentric with the bore. On handguns it is used because the barrel walls can be too thin to allow for a big enough mounting shoulder. As you can see in the example below the AK74 muzzle threads are on the front sight base which is pinned to the barrel. It's unlikely the threads are concentric with the bore. In this case the mount will index off the face of the barrel. You can see where the two come into contact when the mount is threaded on.

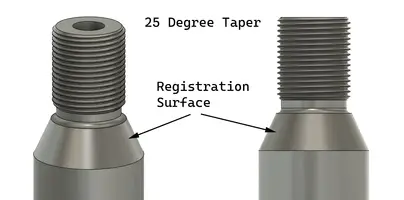

- Taper Indexing - New thing being used by Sig and Q, compatible only with their respective manufacturer's muzzle devices. It's a neat idea and technically superior to the 90 degree shoulder but I think this ship has already sailed. You can see SAAMI has already standardized on a 90 degree shoulder in their recommended thread specs and documentation here. If you have one of these barrels and want to use another brand's muzzle devices that are designed to be compatible with a 90 degree shoulder, You can convert the tapered barrel to a 90 degree shoulder with an adapter. The adapter is a ring that bridges the gap between the taper on the barrel and a 90 degree muzzle device.

What about tri-lugs, should I use one?

Short answer: no, they are garbage.

"But whyyyyyy?" you ask. Let me tell you the reasons:

- The tri-lug was never designed by H&K to be a suppressor mount - Of all the things H&K has designed that connect to a tri-lug mount, none of them has ever been a suppressor. There are plenty of blank firing adapters, flask hiders, muzzle brakes, tear gas grenade launchers, and other official H&K produced accessories that mount to the tri-lug. NONE of them need exact alignment with the bore. You might even notice that the MP5s purchased by the U.S. Navy and supplied with suppressors have threaded barrels. The suppressors that were supplied with those guns attach by threading on to the muzzle, not connecting to the tri-lug. That is enough evidence that the tri-lug is not a suppressor mount. If it was they would have used it.

- The tri-lug does not hold concentric - The tri-lug mount is tensioned by a large spring against the rear of the lugs, that spring is the only thing holding the suppressor temporarily in line with the bore. If you rest the suppressor on a barricade or something knocks it out of alignment while the weapon is being fired you'll probably have a baffle strike. Many such cases.

- There is not a standard size of tri-lug - With all the different manufacturers there is always a decent chance something will not be a compatible dimension between the lugs on the barrel or the mount. If I had a dollar for every time someone said their tri-lug thing from manufacturer A didn't work with manufacturer B's tri-lug thing, I'd be retired.

Get a taper mount like a Rearden Plan-B or Griffin EZ-LOK instead. Either one is a much better idea.

Muzzle thread sizes.

There are some standard thread sizes for muzzle threads

- .22 cal to .38 cal - 1/2-28

- .30 cal - 5/8-24

- .40 cal - 9/16-24

- .45 cal - .578-24

Lubricants, what kind and where to put them.

Two major lubricants are used on suppressors. The more commonly used of these is to lubricate the piston (AKA recoil booster or nielsen device) on handgun suppressors. Use some kind of thick grease to lubricate the piston body, piston spring, and o-ring found in the piston retainer. Lots of people use white lithium. I prefer Super Lube part No. 21030, it's a synthetic grease with teflon that is temp resistant up to 450°F. It's not petroleum based so it doesn't eat o-rings like the one in the piston retainer. It performs very well even after it's wiped off the parts stay slick because of the teflon.

The other kind of lubricant is anti-sieze, you can optionally use a small amount on threads to help prevent them from sticking. Probably some form of ceramic anti-sieze would be best since metal based ones can be messy.

Serviceable vs. Non-Serviceable Suppressors.

You might think that serviceability on a suppressor is a big deal and that it's important to be able to disassemble the suppressor for cleaning. In some cases it is necessary. For instance, .22LR suppressors in which the amount of fouling buildup after 500 rounds can be significant. Lots of pistol cans in the 9mm and .45 sizes can be disassembled for cleaning, they are just designed that way however don't take that as a sign that the baffles need cleaning often. For centerfire rifles, it's not so important because the amount of buildup is minimal. While it is possible to buy a centerfire rifle suppressor that can be disassembled it's not really necessary. The ones that can be disassembled end up being bigger and heavier and generally more clunky than a sealed, fully-welded baffle stack.

When do I clean my suppressor?

How often you should clean depends on what kind of suppressor you have. Having a serviceable suppressor means you can take it apart and remove the baffles for cleaning. Non-serviceable suppressors are welded together at the factory and cannot be disassembled.

- Serviceable .22LR Suppressor - Clean it every 500 rounds or so.

- Non-serviceable .22LR Suppressor - Have fun buying gallons of proprietary suppressor cleaner from the manufacturer. Read the manual and do whatever the manufacturer recommends.

- Serviceable pistol suppressor - Clean the baffles every 1500 rounds. Clean and lubricate the piston after every range trip.

- Serviceable rifle suppressor - Clean it every 1500-2000 rounds or so. If you've been shooting .22LR through it use the .22LR schedule.

- Non-serviceable rifle suppressor - Don't bother.

On centerfire suppressors it's really more important to clean the mounting system than to clean the inside of the suppressor. If you have a QD mount it's a good idea to clean the tapers on the muzzle device and inside the mount after every range trip.

All the stuff on this page, text, thumbnails, images are licensed under CC BY-NC-SA 4.0